System Integrity

Smart PIGS Help Ensure Safe Pipelines

Pipeline systems are the arteries of our business. Maintaining the health of those arteries ensures that we fulfill federal and state compliance requirements, while meeting customer needs and realizing our environmental and safety goals.

At ONEOK, Pipeline Integrity Management Is a Team Effort

Pipeline integrity begins with pipeline design and construction management practices and continues with daily operation activities for the life of the asset.

- Engineering, Construction and Right-of-Way teams manage pipeline design, routing and encroachment agreements, following best practices that help ensure newly laid pipelines are ready for service and damage free.

- Corrosion Control develops coating selection specifications and best practices for coating application, working with Construction to ensure contractors meet our expectations. They also model, design and install cathodic protection systems and induced high-voltage alternating current corrosion mitigation systems. Internal treating and monitoring programs are implemented for systems susceptible to internal corrosion.

- The Department of Transportation (DOT) Compliance team provides engineering design reviews and helps protect the pipelines from physical damage via the combined efforts of Geographic Information Systems personnel, One Call and Aerial Patrol.

- Field Operations and Pipeline Control ensure pressure control equipment and compressor and pump stations operate within design limits. Field personnel engage daily in One Call responses and encroachment oversight and actively monitor atmospheric corrosion.

ONEOK’s pipeline integrity management has evolved a “cradle to grave” scope for newly constructed pipelines. However, we operate pipeline systems of varying ages – designed and constructed with the knowledge and technology of the time -- which makes identifying, evaluating and mitigating existing pipeline damage especially important to our pipeline integrity program effectiveness.

Smart PIGs Help Ensure Safe Pipelines

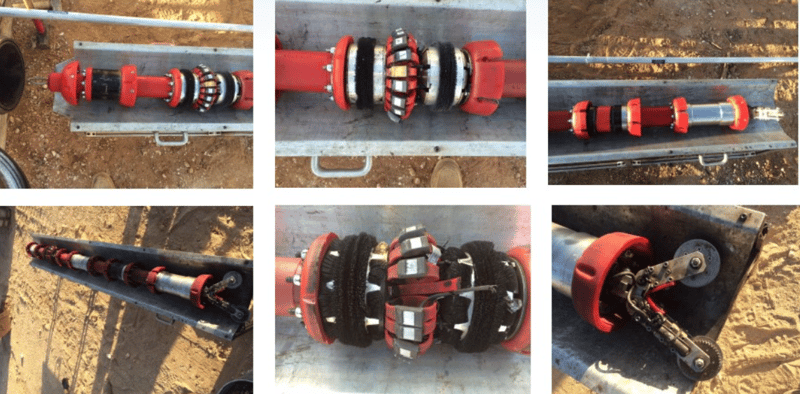

PIG is an acronym for pipeline inspection gauge, which refers to a variety of tools that sweep liquids and solids from a natural gas pipeline or unwanted liquids and solids from a natural gas liquids pipeline.

ONEOK’s Pipeline Integrity team uses the smart pig in-line inspection tool to assess the condition of pipelines. Simply put, smart pigging basically puts a computer inside of a mechanical cleaning pig. As product in the pipeline propels the pig through, it measures and records irregularities such as corrosion, cracks and other defects.

Smart pigging, in-line inspection and intelligent in-line inspection (ILI) are umbrella terms for different types of tools used to assess pipeline conditions. ONEOK selects the most appropriate technology depending on known or expected threats to a given pipeline segment. Provided by various vendors, the tools can provide data indicating:

- Internal and external corrosion anomalies called pits.

- Other metal loss features caused by mechanical damage.

- Cracks.

- Deformations, including dents and buckles.

- Location of anomalies lengthwise down the pipe segment and circumferentially on the pipe diameter.

- Movement or strain, although less frequently.

Pig Selection and Data Evaluation

The most commonly used tools in the industry are magnetic flux leakage (MFL) and deformation tools. MFL tools have very powerful magnets that magnetize the pipe and sensors to measure the magnetic field. If the nominal pipe wall thickness is 1/4-inch thick, the magnets will produce – and sensors will measure – a uniform and consistent magnetic field for that area of pipe.

If metal is missing from that consistent pipeline wall thickness, it disrupts the magnetic field. Based on the changes in the magnetic field, a prediction is made of how much metal loss has occurred.

Data generated by the tools is evaluated by qualified analysts and computer models and reports are then submitted to ONEOK.

Wall thickness is a key variable in design calculations for maximum safe operating pressure. Calculations, using industry and regulatory-accepted formulas, determine if further evaluation is necessary. If needed based on the predicted data, the pipe is excavated to confirm anomaly depth and length. Next, a final repair determination is made.

Combining MFL tools with deformation tools offers the advantage of running a single tool to gather multiple data sets. Deformation tools have spring-loaded “fingers” that measure dents and other deformations in the pipeline.

Pipeline Integrity also has used electromagnetic acoustic transducer tools to help identify cracks and cracklike anomalies.

Through risk modeling, data integration and growth analysis, Pipeline Integrity determines the appropriate assessment interval for a pipeline segment. This may result in more frequent assessments than required by regulation.

Assessments are not just for the sake of maintaining compliance. ONEOK wants to keep our pipelines performing as they are designed. If an anomaly exists that could impact safe operations, our environmental goals or customer service, we want to find it and fix it before it finds us.

More Facts About Pipelines and Smart Pigs

- The types of products transported and the speed the tool travels may impact the effectiveness and accuracy of in-line inspection tools.

- Tool weights may range from 20 pounds for smaller diameters to more than 800 pounds for larger diameters.

- Regulated natural gas liquids pipelines that could impact a “high-consequence area” must be inspected at intervals not to exceed five years. High-consequence areas are those along a pipeline that could impact people, an environmentally sensitive area, navigable waterways and ecological areas.

- Regulated natural gas pipelines that could impact a high-consequence area must be inspected at intervals not to exceed seven years.

- Other assessment types are allowed under the regulations, such as a hydrostatic pressure test or direct assessment.

- Assessment type is based on known or predicted threat categories. Generally, ILI provides more data with less impact to operations.

- Assessments also provide additional key performance metrics for the prevention side of pipeline integrity management.

- The Pipeline Integrity group presents an annual review of activities and findings to ONEOK’s Natural Gas Liquids, Natural Gas Transmission and Natural Gas Processing business unit leaders.

- The scope of work managed by Pipeline Integrity is significantly more comprehensive than the assessment and remediation activities related to in-line inspection covered herein. Additionally, federal and state regulatory agencies will conduct as many as 40 to 50 weeks of detailed program compliance inspections each year, and pipeline integrity management is often the central focus.